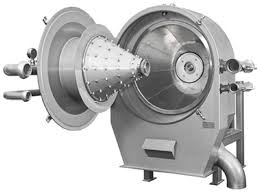

Centrifugal sieves ST/300 are designed and constructed to efficiently remove lumps, foreign bodies and husks from powders and milled products. They can also be used to remove dust & fines from granular materials. Beccaria rotary powder sifters have been constructed to meet or exceed the requirements of ATEX Directive 94/9/EC.

The rotary action of the paddles agitates the product which helps break up agglomerations, this reduces the amount of good material which is lost. The fines exit the sieve under the main body of the machine whilst the coarser material travels through the sifting drum and exits at the outlet at the end of the sifter. The advantage of the cantilever design is that it allows complete unimpeded access to the end of the end of the shaft where there are no bearings.

Material enters the sieve through the feed hopper located at one end of the sifter. Beccaria rotary sieves are of a cantilever design. A central shaft supported by bearings only at one end runs through the middle of the machine. Mounted to the first portion of this shaft is a short auger which transfers product from the feed hopper into the sifting cylinder. On the next part of the shaft there are a series of paddles which rub the product against the inside of the sieving mesh.